• The GOMACO 3300 features a symmetrical design for right-side and left-side slipforming.

• The 3300’s ability to pave on the right-side is an advantage for paving operations, because it allows a contractor to pour in the same direction as traffic.

• GOMACO’s 3300 features a U-shaped operator’s platform which is the ideal shape for ultimate operator visibility when pouring from either side of the machine.

• The operator’s platform is isolated for optimum operator comfort throughout a day of paving.

• The unique frame design, multiple smart sensors, and GOMACO’s G+® control system allows the 3300 to automatically slipform a tight radius with ease.

• The operator’s console slides from the right side to left side depending on which side the mold is mounted. The console can be locked away and out of sight when not in use.

• GOMACO’s 3300 is equipped with a 17 foot (5.18 m) charging auger or 20 foot (6.1 m) folding conveyor for loading the hopper from either side of the machine.

• The 3300 features GOMACO’s simultaneous trim/pour concept.

• GOMACO’s 3300 can slipform multiple applications such as curb & gutter, safety barrier, sidewalk, and undermounted slipform paving.

• The 3300 is designed with safety features to give years of safe and dependable service.

GOMACO 3300 Multi-Application Concrete Slipform Paver

4 minutes 23 seconds

GOMACO 3300 Concrete Slipform Paver Performance Report

Cranbury, New Jersey

4 minutes 14 seconds

This GOMACO 3300 is equipped with a sideshifting trimmerhead and curb mold. The 3300 features the smart telescoping mold mounting system with feedback to the G+ controls for repeatable mold off set. The mold and trimmer can be hydraulically lifted over obstacles found on the job site.

The charging auger on the 3300 is equipped with vibration to release concrete build up from the safety guard at the end of the hopper. The auger’s safety guards are hinged to allow for cleaning.

A 3300 with Topcon mmGPS 3D guidance is slipforming concrete barrier over steel reinforcing on a bridge on U.S. Highway 183 in Leander, Texas.

Xtreme Design

Extreme steering capabilities are standard on the 3300 with rotary-sensored slew drives on each track. The two front legs are mounted on parallelogram-style pivot arms allowing for adjustments out from the right side and left side of the machine. The rear power-slide leg can be positioned to the right or left of center. The front leg pivot arms and power-slide on the rear leg allow for correct positioning feedback through G+® control. Smart leg positioning and smart steering provide the 3300 with correct steering angles through a radius.

Xtreme Hydraulic Package

Independent hydraulic travel control to each track allows G+ to control the individual track’s speed through a radius.

Xtreme Steering Capabilities

The 3300 is equipped with rotary-sensored slew drives on each of the three tracks for extreme steering. The extreme steering capabilities, combined with the 3300’s sensored All-Track Steering and sensored All-Track Positioning, make it the ultimate intelligent slipform paver. The intelligent All-Track Positioning on the 3300 includes a smart hydraulic cylinder on each of the three legs. The smart cylinders allow G+ control to know the position of all three tracks to make steering adjustments as needed.

Xtreme Radius

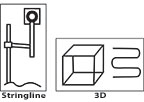

The GOMACO 3300 can pour a 24 inch (610 mm) radius. The 3300 G+® control system easily interfaces with stringline or a 3D guidance system for curb and gutter and tight radius applications. The 3300 features the GOMACO three-sensor radius system for stringline. When paving with stringline, the lead steering wand is allowed to leave the stringline and reference is switched to sensor number two for traveling around the tight radius. Individual track speed control provides smooth machine travel around the radius.

G+ Radius Software For Stringline Operation

Choose your radius and G+ calibrates and manages all aspects of traveling around the radius, including track angles and individual variable track speeds. The G+ radius software for the control system allows the operator to program the size of the radius into the controller. As the 3300 approaches the radius, with the values already dialed in, the operator activates the radius program, and the curb and gutter machine slipforms around the radius.

Xtreme Intelligence

Smart cylinder sideshifting of the mold provides G+ the ability for repeatable mold off set. Intelligent off set is accomplished with a smart hydraulic cylinder for telescoping the mold mounting system. The trimmerhead and mold have independent vertical adjustments allowing each to raise and lower separately.

Each track is equipped with rotary-sensored slew drives for extreme steering. The conveyor has four-way hydraulic positioning which is located between the two front legs. The four-way positioning cylinders provide pivoting tilt, pivoting swing, longitudinal slide, and sideshifting of the conveyor.

Hook & Go

GOMACO’s Hook-and-Go mold mount system has no pins or latches and makes it quick and easy to change molds. Simply drive the 3300 up to the mold and hook the mount to a special attachment plate. The mold is then hydraulically lifted up and can go to work slipforming the project... just hook and go. Tight-clearance paving is accomplished with the sideshifting capability of the mold on the GOMACO 3300.

Repeatable Mold Offset

The 3300 features intelligent off set which is accomplished with smart hydraulic cylinders for telescoping the mold mounting system. This provides G+ the ability for repeatable mold off set. The mold can be hydraulically lifted over obstacles found on a job site. The GOMACO 3300 also features All-Track Steering (ATS) allowing the 3300 to slipform tight radius work and allows the machine to move easily around the job site. ATS saves time getting on and off stringline, job-site mobility, and loading and unloading for transport. The ability to steer all of the tracks allows accurate steering around tight radii.

Trimmer & Trimming Power

The GOMACO 3300 slipform paver features a sideshifting and vertical adjusting trimmerhead and mold. The trimmerhead has a maximum hydraulic sideshift distance of 48 inches (1219 mm) and an 18 inch (457 mm) hydraulic vertical adjustment for slipforming right up to the obstacle before lifting up to go over the obstacle to continue paving. The trimmerhead is directly driven with a radial piston hydraulic motor which provides maximum torque for trimming capacity.

Fast Loading Provides Increased Production

Fast concrete loading provides high-production results. There are two concrete delivery systems to choose from with the GOMACO 3300, the charging auger and the folding conveyor. The 17 foot (5.18 m) long, 16 inch (406 mm) diameter charging auger provides fast and efficient concrete flow with an auger speed variable up to 88 rpm. The charging auger features vibration at the end of the hopper allowing concrete build-up to be released. The vibration is manually activated by the ground personnel.

The conveyor is 20 feet (6.1 m) long, 24 inches (610 mm) wide, and has a belt speed variable up to 254 feet per minute (77.4 mpm). It is hydraulically powered and reversible with a charging hopper. The conveyor is pivot mounted with hydraulic lift and positioning. The mold is designed with extra concrete capacity, to allow slipforming through a tight radius without waiting for concrete truck repositioning.

GOMACO’s Hook-and-Go mold mount system on the 3300.

GOMACO’s 3300 equipped with a curb and gutter mold on the right-side.

GOMACO’s 3300 with right-side barrier mold.

GOMACO’s 3300 can be equipped with an undermounted mold.

It is now the technology that pulls everything together… G+ is the center that Connects all of the resources.

Once you experience G+ controls, you won’t be satisfied with anything else. It’s a control system that is both easy to learn and easy to operate. G+ expresses itself in easy to understand international icons and full script explanations. It operates in all the major languages of the world and in imperial or the metric system. It has a lightning-fast processing speed and features two-way communications between the accessories and G+. Its instant digital feedback combined with the tight closed-loop electronic and hydraulic control creates a G+ experience that is smooth, efficient, and accurate. There is nothing on the market that can compare, because G+ is a proprietary system that was designed by our in-house control experts incorporating what we have learned from decades of experience in the field, and from what we have learned from you, our customer.

- Machine operation is simple.

- Machine response is fast.

- Troubleshooting is pinpointed, quick, and easy.

- Fault history available.

- Control from stringline, 2D, or 3D guidance.

A flat-panel 6.5 inch (165 mm) anti-glare display screen is provided with sensor-controlled backlight levels for superior visibility in all operating conditions. The screen is rugged and shock resistant in its construction to protect against dust, moisture, and rain. G+ provides a full color display on the control panel to illustrate the current operational functions of the paver for set up and operation. A “run” screen on the control panel illustrates the various aspects of the paver. It includes leg position, paving speed and percentage of drive, steering, travel information, grade information, deviation meters, and more. Newly designed icons and color graphics make it easy to understand and easy to identify the targeted functions. G+ receives a track speed reading from pulse pickups in the track motors to give you real time feet (meters) per minute and total linear footage (meters). G+ controls feature a detailed fault history with the time stamp, date, and information to track when each fault occurred. GOMACO’s G+ control system has been proven around the world.

Auto Steer Mode

Coordinated Steer

Crab Steer

Front Steer

Rear Steer

A 3300 with an undermounted mold and 3D machine guidance slipforms a highway ramp eight feet (2.44 m) wide, 12 inches (305 mm) thick. The 3300’s tracks are turned 90 degrees in the transverse position to accommodate the undermounted mold.

The 3300 is carefully designed to give years of dependable and safe service. The emergency stop buttons are on the operator’s console and on the corners of the machine, which are easily accessible from the ground level. The machine is equipped with a backup alarm, which is designed to alert personnel around the machine when the tracks are set to operate in reverse. Other safety features include track guards, warning decals, operator horn, an operator’s manual, and a safety manual. GOMACO machines are also designed to provide the operator with excellent visibility over the entire paving operation.

ENGINE

Consult for options available.

SERVICE CAPACITIES

Fuel reservoir: 70 gal. (265 L).

Hydraulic oil reservoir: 89 gal. (337 L).

AUTOMATED CONTROL SYSTEM

Type: Electronic-over-hydraulic.

Controls: GOMACO’s exclusive G+® control system for paving accuracy and ease of operation. It features multi-language, metric or imperial settings, and a 6.5 in. (165 mm) anti-glare display screen.

Control indicators: Color graphical performance indicators allow operator to monitor control signals for machine guidance on stringline or 3D.

WATER SYSTEM

Type: On-board water system.

Capacity: One 100 gal. (379 L) high-pressure water tank with trigger gun control and adjustable pressure unloader for up to 2000 psi.

SLIPFORM MOLD

Curb and gutter mold: One curb and gutter mold. Optional molds available for curb and gutter, barrier, parapet, and sidewalk.

VIBRATORS

Type: Hydraulically powered, motor-in-head, variable speed, independently controlled, and synchronized with machine movement.

Quantity: Two vibrators and four circuits are standard.

MOLD DRAWBAR AND HOLD-DOWN ASSEMBLY

Hydraulic lift: 18 in. (457 mm) pressure-compensated hydraulic vertical adjustment with 26 in. (660 mm) manual vertical adjustment.

Sideshift: 36 in. (914 mm) maximum hydraulic sideshift.

SUBGRADE TRIMMER (sectionalized)

Direct-drive trimmerhead: Trimmerhead is directly driven with a radial piston hydraulic motor which provides maximum torque for trimming capacity. 24 in. (610 mm) diameter trimming wheel.

Trimmer wheel rotation: Upward cut.

Width: 30 in. (762 mm) to 66 in. (1676 mm) sectionalized trimmerhead with hydraulic sideshift capability.

Sideshift distance: 48 in. (1219 mm) maximum hydraulic sideshift.

Hydraulic lift trimmer: 18 in. (457 mm) hydraulic vertical adjustment, with 6 in. (152 mm) manual vertical adjustment.

CHARGING AUGER

Drive: Direct drive via radial piston hydraulic motor.

Length: 17 ft. (5.18 m).

Auger diameter: 16 in. (406 mm).

Auger speed: Variable up to 88 rpm.

Auger mount: Features 42 in. (1067 mm) hydraulic slide adjustment and hydraulic pivoting mount (slide and tilt) for negotiating discharge from the ready-mix truck and negotiating grade variations.

Wear surface: Features replaceable auger flight liners.

CONVEYOR

Type: Hydraulically powered, reversible with charging hopper. Pivot mount conveyor with hydraulic lift and positioning.

Length: 20 ft. (6.1 m) folding conveyor with hydraulic lift, shift, and pivot.

Width: 24 in. (610 mm).

Belt speed: Variable up to 254 fpm (77.4 mpm).

Belt wiper: Features special blades on adjustable spring steel rods for superior cleaning results. The unique, no-maintenance troughing rollers are greaseless and self-cleaning.

Conveyor mount: Features 42 in. (1067 mm) hydraulic slide adjustment and hydraulic pivoting mount (slide and tilt) for negotiating discharge from the ready-mix truck and negotiating grade variations.

Hopper: Designed for more concrete capacity to allow slipforming a complete radius without waiting for concrete delivery.

TRACK SYSTEM

Type: Three hydraulically powered, gear-driven crawler tracks.

Overall track length: 5.1 ft. (1.6 m).

Track pad width: 11.8 in. (300 mm).

Track speed: Variable up to 49.5 fpm (15.1 mpm); auxiliary variable up to 131 fpm (39.93 mpm).

Leg height adjustment: Each track has 36 in. (914 mm) hydraulic adjustment and an additional manual adjustment of 8 in. (203 mm).

Front legs: The two front legs are mounted on parallelogram-style pivot arms.

Power-slide leg for positioning rear track: Hydraulically controlled, allows up to 5.9 feet (1.8 m) lateral track movement.

SHIPPING DIMENSIONS

Overall length with folded conveyor: 25.1 ft. (7.65 m).

Overall length with unfolded conveyor: 31 ft. (9.45 m).

Overall length without conveyor: 22.3 ft. (6.8 m).

Overall length with auger: 28.7 ft. (8.75 m).

Overall height: 9.1 ft. (2.77 m).

Overall width: 8.3 ft. (2.53 m).

WEIGHT (approximate)

28,000 lbs. (12,701 kg). Weight can vary depending on size of mold and options.

Note: Transport and operational weights and dimensions are variable, depending on machine options.

OPTIONS

One additional 100 gal. (379 L) water tank.

Guillotine-style curb depressor has a straight blade that enters the face of the curb. Hydraulically powered, for use on curb and gutter molds while slipforming through driveways. Can be changed to other molds if they are slotted and clamped to accept the driveway cutout.

California-style curb depressor has a curved blade that enters the face of the curb. Hydraulically powered, for use on curb and gutter molds while slipforming through driveways.

Hydraulic pressure-compensated sideplates.

Additional vibrators and mounts.

Additional vibrator circuits and controls.

Left-hand or right-hand discharge trimmerhead.

Trimmerhead insert sections of 12 in. (305 mm), 18 in. (457 mm), 24 in. (610 mm), and 30 in. (762 mm) widths are available for trimmerhead width up to 66 in. (1676 mm) maximum.

Additional molds built to customer specifications. Various mold options are available.

Polyurethane track pads, 81 pads required.

Radius wheels for use on radius work, saving time on stringline set-up.

3D package for machine guidance.

GOMACO Remote Diagnostics (GRD) available.

Other options are available to customize the machine to accommodate applications and customer needs.