GOMACO World Index --- GOMACO World 28.3 - December 2000

Step by Step: IDBI

In-The-Pan Dowel Bar Inserter

The IDBI is a fully automated system for two- or four-track pavers. The computer controls the time and operation of the IDBI functions. The process starts with every tray being loaded with a dowel bar by a trolley traveling across the paving width. The accuracy of this patented loading system accounts for the proper number of bars inserting into the slab (right). Several of the IDBI concepts, systems and components hold United States and International patents.

The following pictures offer a brief explanation of the insertion process...

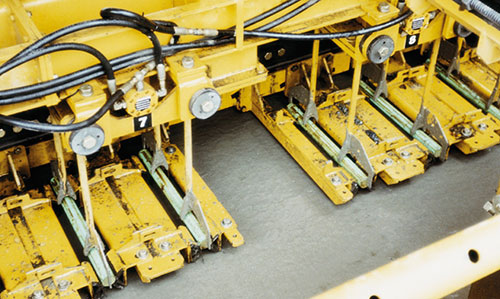

Bars are held in the bar-holding tray while the forks wait in stand-by mode for the insertion point to be signaled by the IDBI computer. The bar loading tray has been redesigned so moderate center-to-center bar spacing can be changed for different job specifications.

Vibration is applied to the forks on insertion to consolidate and close the concrete around the inserted bars. The paver never stops during the insertion process. GOMACO's exclusive computer-controlled smart-cylinder technology provides the state-of-the-art system to maintain the accountability of the depth of the bars upon insertion into the slab.

Subscribe to Receive GOMACO World Magazine