• The GOMACO GP4 is designed for paving up to 40 feet (12.19 m) wide and to accommodate multiple width changes. The GP4 is available as a two-track or four-track slipform paver.

• The exclusive G+® control system easily interfaces with stringline or 3D machine guidance to slipform all of your project needs.

• GOMACO’s GP4 two-track and four-track slipform pavers have dual-telescoping capabilities of up to seven feet (2.13 m) on each side of the paver, for a total of 14 feet (4.26 m) of automatic frame widening.

• Smart cylinders in the roller frame provide the width reference to the G+ controller and uses that information for steering setup and individual track speed control through radii.

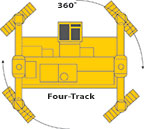

• The four-track GP4’s smart leg positioning includes rotary-sensored slew drives on the pivot arms of each of the paver’s legs. The smart pivots on the legs provide the G+ control system with information on the pivot arm angle and works together with the track rotation sensors to maintain the tracks in the straight-ahead steering line.

• Rotary-sensored slew drives are also located on all four tracks for the ultimate in smart steering technology and extreme steering with the tracks having the ability to steer farther than ever before.

• The GOMACO four-track GP4 easily turns radii with smart leg positioning and smart track rotation.

• The GP4 slipform paver has been designed for easy transport.

• G+ allows quiet running technology with its ability to control the cooling fan speed based on temperature inputs from the engine and hydraulic oil. Based on these inputs, the cooling fan can run at a slower speed producing less noise. G+ load-sensed hydraulics provide maximum paving performance and optimized fuel efficiency.

• The GOMACO GP4 has an isolated operator’s platform for operator comfort during a long day of slipform paving.

• The optional GOMACO Navigator allows the paver's smart accessories to be easily monitored and controlled.

• GOMACO Remote Diagnostics (GRD) is an available option that is so much more than telematics, giving owners the visibility of how, when, and where their equipment is being used.

GOMACO GP4 Slipform Paver & T/C-5600 Texture/Cure Machine

Phoenix-Mesa Gateway Airport; Phoenix, Arizona

2 minutes 16 seconds

Odessa International Airport Footage; GOMACO GP4 Slipform Paver With IDBI

Odessa, Ukraine

2 minutes 43 seconds

GOMACO GP4 Slipform Paver & IDBI

I-70; Near Limon, Colorado

3 minutes 24 seconds

GOMACO GP4 Slipform Paver

Detroit Metropolitan Wayne County Airport; Romulus, Michigan

6 minutes 38 seconds

GOMACO GP4 Slipform Paver, PS-2600 Placer/Spreader and T/C-600 Texture/Cure Machine

Salem, South Dakota

5 minutes 47 seconds

The four-track GP4 slipforms a 36 foot (10.97 m) wide interstate project. The GP4 is equipped with a telescoping spreader/plow to move the concrete evenly across the grade ahead of the mold. An IDBI (Independent Dowel Bar Inserter) and 5400 series tie bar inserter place the bars according to the project specifications set forth by the DOT (Department of Transportation).

This GP4 four-track paver with 3D machine guidance slipforms a country road 26 feet (7.92 m) wide and is equipped with a 5400 series mold and 5400 series tie bar inserter (TBI).

The GP4 is capable of paving widths up to 40 feet (12.2 m) wide and is the ideal paver for airport work when exacting smoothness and edge slump requirements must be met using difficult concrete mix designs.

Read more about this project in GOMACO World 46.1.

This contractor was able to utilize their existing attachments and sensors from their GOMACO GP-4000 paver on their new GP4 with G+ control system.

A four-track GP4 slipform paver works on a concrete runway project at the Detroit Metropolitan Wayne County Airport in Michigan.

A PS-60 spreads concrete ahead of the four-track GP4 equipped with an IDBI (Independent Dowel Bar Inserter) and two 5400 series tie bar inserters to place the dowel bars at DOT (Department of Transportation) specifications on this interstate project. The IDBI is an independent attachment that is self-contained, self-powered, and inserts transverse dowel bars into the pavement.

This four-track GP4 concrete paver is slipforming 18.75 feet (5.7 m) wide and 20 inches (508 mm) thick on the Charlotte-Douglas International Airport in Charlotte, North Carolina. The paver is equipped with Leica 3D guidance, a 5000 series open-front mold, a 16 inch (406 mm) auger, and a diverter plow.

This two-track GP4 is paving in Jacksonville, Arkansas. It has trailing form side bar inserters, spreader plow, drag pan, and low-profile, mold-mounted GSI® units.

It is now the technology that pulls everything together… G+ is the center that Connects all of the resources.

Once you experience G+ controls, you won’t be satisfied with anything else. It’s a control system that is both easy to learn and easy to operate. G+ expresses itself in easy to understand international icons and full script explanations. It operates in all the major languages of the world and in imperial or metric units. It has a lightning-fast processing speed and features two-way communications between the accessories and G+. Its instant digital feedback combined with the tight closed-loop electronic and hydraulic control creates a G+ experience that is smooth, efficient, and accurate. There is nothing on the market that can compare, because G+ is a proprietary system that was designed by our in-house control experts incorporating what we have learned from decades of experience in the field, and from what we have learned from you, our customer.

- Machine operation is simple.

- Machine response is fast.

- Troubleshooting is pinpointed, quick, and easy.

- Fault history available.

- Control from stringline, 2D, or 3D guidance.

A flat-panel 6.5 inch (165 mm) anti-glare display screen is provided with sensor-controlled backlight levels for superior visibility in all operating conditions. The screen is rugged and shock resistant in its construction to protect against dust, moisture, and rain. G+ provides a full color display on the control panel to illustrate the various aspects of the paver for set up and operation. A “run” screen on the control panel illustrates the various aspects of the paver. The “run” screen includes leg position, paving speed and percentage of drive, steering, travel information, grade information, deviation meters, and many more features that can be used when slipform paving. Newly designed icons and color graphics make it easy to understand and easy to identify the targeted functions. G+ receives a track speed reading from pulse pickups in the track motors to give you real-time speed and total distance traveled. G+ controls feature a detailed fault history with the time stamp, date, and information to track when each fault occurred. GOMACO’s G+ control system has been proven around the world.

The GP4 slipform paver is designed for easy transport. The operator can take the paver to the transport mode in minutes without assistance. The paver can be switched to the transport mode by simply rotating the legs to the transport position. After the legs are in the transport position, G+ travel is switched to “Transport” for complete control. A retractable, sliding console reduces the shipping width of the machine.

G+ knows the width of the paver’s dual-telescoping frame. Changing the width of the slipform paver’s mainframe is accomplished with the Smart Cylinders and GOMACO roller frame.

The smart width provides easy, accurate width change setup and a reference for G+ to control proper steering and track speeds while turning a radius at varying widths of the paver.

Pivot arms for the paver legs feature rotary-sensored slew drives. These smart pivots provide the G+ controls with information on the pivot arm angle, which coupled with the track rotation sensors, maintain the tracks in the straight-ahead line for steering, even when the leg pivot is at an angle.

Track steering and rotation is accomplished with rotary-sensored slew drives. This smart track rotation provides the G+ controls with exact track location and position. Extreme steering is now possible with the tracks having the ability to steer farther than ever before.

Smart leg pivoting and smart track rotation now lets the G+ system automatically control the direction and speed of each individual track as it travels through a radius.

Auto Steer Modes

Coordinated Steer

Crab Steer

Front Steer

Rear Steer

Counter-Rotation

The GP4 is carefully designed to give years of dependable and safe service. The emergency stop buttons are on the operator’s console and on the corners of the machine, which are easily accessible from the ground level. The machine is equipped with a backup alarm, which is designed to alert personnel around the machine when the tracks are set to operate in reverse. Other safety features include track guards, warning decals, operator horn, an operator’s manual, and a safety manual. GOMACO machines are also designed to provide the operator with excellent visibility over the entire paving operation.

GOMACO CORPORATION RECOMMENDS THE IMPLEMENTATION OF ALL SAFETY PROCEDURES.

This four-track GP4 slipform paver is equipped with a telescoping spreader plow to evenly spread the placed concrete across the grade.

This four-track GP4 is slipforming an airport runway 37.5 feet (11.43 m) wide and 17 inches (432 mm) thick using 3D machine guidance. The GP4 features an aluminum work bridge and is equipped with the 5400 series mold which produces a smooth, clean, and sharp GOMACO edge.

Sensored steer feedback with sensored leg pivots provide continuous reference for the straight-ahead track positioning.

Full-steer tracks are turned perpendicular to the straight-ahead line. The G+ control system recognizes the track positioning and provides automatic steering control in the transverse mode.

Full-steer tracks and hydraulic rotational sensored pivot arms allow the legs to be rotated to the transport position. Track direction of travel and steering control is automatic with the G+ control system.

This four-track GP4 features a plow on the front to evenly spread the concrete across the paving surface.

The control tower for the Phoenix-Mesa Gateway Airport can be seen behind the GP4 paver as it slipforms a new 3500 foot (1067 m) long, 75 feet (22.9 m) wide curbside-rated aircraft taxiway.

An RTP-500 places concrete on the grade in front of a GP4 on the Detroit Metropolitan Wayne County Airport.

The GP4, four-track, slipforms highway expansion at 38 feet (11.58 m) wide. The GP4 is equipped with the 5400 series paving mold, an Auto-Float®, and 3D machine guidance.

(1) The spreader/auger on the 3100 series open-front mold is a 14 inch (356 mm) auger with a maximum speed of 33 rpm. The spreader/auger on the 5000 series open-front mold has a 16 inch (406 mm) auger and maximum speed of 28 rpm.

(2) Vibration is provided to the throat area of the mold for consolidation of concrete. The vibrators, with an automatic on/off control, activated with machine movement, are hydraulically powered with variable speeds up to 10,500 vpm. The vibrator position is hydraulically controlled for start of paving and lifting over the bulkhead to finish paving.

(3) The GOMACO tamper bar system tamps down the aggregate level below the surface of the pan. The tamper bar is hydraulically powered with an automatic on/off control, activated with machine movement.

(4) The 3100 series mold and stainless is 48 inches (1219 mm) from front to back. The 5000 series mold and stainless is 60 inches (1524 mm) from front to back.

(5) Adjustable stainless steel is exclusive to the GOMACO paving mold systems.

This GP4 slipform paver features a 5000 series mold with an Auto-Float® to complete a smooth finish across this airport project.

• 5400 series paving mold features a box design with durable 0.5 inch (13 mm) thick paving skin.

• Vertically-adjustable mold mount for precise leveling of mold to machine.

• Telescoping end sections with 24 inches (610 mm) of width variation on each side are optional.

• Edge slump adjustment.

• Hydraulic Vertical Hinged Sideplates, self-contained inside the mold.

• Pressure-compensated sideplates are standard.

• Split sideplates are optional on the 5400 series paving mold.

• Folding sideplate wings for transporting without removing.

• Pivoting mold mounting beam to eliminate stress points, created by crowning the mold.

• Self-supported power transition adjuster (PTA) is hydraulically driven with 3.5 inch (89 mm) ACME screws for up to a six inch (152 mm) crown.

• Front and rear top T-bar on mold for attaching accessories and structural integrity.

• Inserts are bolted together with front and rear alignment pins for easy mold assembly.

• Vibrator mounting tube attaches to T-bar on mold.

– Vertical vibrator lift.

– Rear lubrication system with grease zerks accessible from the work bridge.

• Tamper bar optional.

• Trailing stainless optional.

This 5400 series paving mold is equipped with two telescoping end sections and has seven 36 inch (914 mm), one 30 inch (762 mm), and three 24 inch (610 mm) mold sections. The 5400 series paving mold also features edge slump adjustment and a self-supported PTA. 5400 series paving molds can be equipped with one or more bar inserters.

Telescope the end section out and add your desired insert size, along with the front insert plate, into the 5400 series mold. Then retract the telescoping end section and resume paving.

GOMACO 5400 Series Concrete Slipform Paving Mold For GOMACO Concrete Slipform Pavers

3 minutes 50 seconds

GOMACO 5400 Series Concrete Slipform Paving Mold, Telescoping End Section

3 minutes 25 seconds

Bar Insertion Systems Designed to Fit Your Project Specifications

GOMACO offers several bar insertion systems that are designed to accommodate your project specifications. Hydraulic cylinder, air-powered, and manual insertion are the three types of bar insertion. Bar inserters include the frame-mounted, sidemounted, 5400 series, and trailing form. GOMACO’s bar inserters provide easy and accurate bar placement to job specifications.

5400 Series Bar Inserter

The 5400 series bar inserter is front or rear loading and front inserting for ease of use. It mounts to the mold's T-bar and allows on-the-go crown changes, while maintaining a constant depth. The bar box is mounted to the paver's rear T-beam mounting rail for easy access and loading of the bar magazine. There are individual depth guides on the right and the left side of the bar inserter in order to keep bars parallel to the top of slab. The 5400 series bar inserter can hold up to 50 bars in the bar magazine and bar loading chain system.

The trailing form with manual, air-powered, or hydraulic bar insertion is designed to trail the track on two-track pavers. This system will accommodate most types of bars.

The hydraulic system includes vibration to the bar, and is designed for large bars. Vibration is applied to the bar during insertion, which provides consolidation of concrete around the bars. The minimum slab depth required is six inches (152 mm) and the maximum bar length is 48 inches (1219 mm).

The four-track paver’s hydraulic powered bar inserter is located in front of the rear paver leg at the end of the mold.

Trailing Form and Bar Inserter

The trailing form and manual bar inserter is designed to trail the track on a two-track paver. This system will accommodate most types of bars.

• The GOMACO Navigator software and display screen is an optional add-on for your paver to bring all of your G+ paver accessories together for easy control and monitoring.

• The touchscreen can be mounted at ground level on the paver to allow personnel the ability to fine tune the slipform paver's performance and configure settings for the GSI® (GOMACO Smoothness Indicator), SBI (side bar inserter), TBI (tie bar inserter), and PTA (power transition adjuster).

• Ground personnel can monitor the elevation and steering deviations for the machine and adjust sensitivities when required. The deviation meters are customizable and can be shown in a G+ bar graph, circular, or oscilloscope/histogram mode.

• The Navigator can be configured to make G+ accessories available on older G21/G22 slipform pavers.

Navigator G+ paver home screen shown.

• The ACC (Accessories) tab on the Navigator will allow ground personnel to monitor the real time operation of the tie bar inserter (TBI), side bar inserter (SBI), and power transition adjuster (PTA).

• The Navigator supports up to four PTAs. To transition the PTAs, simply enter the new target height values for each PTA, enter the transition distance, and press start transition. The yellow line represents the current height of each PTA, and the red line represents the target height for each PTA.

• Up to four TBIs and two SBIs are supported on the Navigator. The machine position in relation to the current dowel bar spacings is indicated by the red vertical line that will travel across the screen when the machine is moving. When the paver (red line) passes a TBI/SBI fire position, the fire lamps are illuminated.

ACC (Accessories) Screen shows how many PTAs, TBIs, and SBIs are set up on the paver, and the distance between them.

Personnel enter the number of bars required between each horizontal joint into the TBI/SBI setup menu. Navigator then calculates the space between each bar and the horizontal joint and makes managing bar placement simple and easy.

• The GSI (GOMACO Smoothness Indicator) screen on the Navigator allows ground personnel to monitor paving smoothness for up to four GSI traces (two visible at a time) using either a real-time localized roughness graph or a simulated California profilograph.

• The machine speed is now logged, which makes it possible to relate the machine speed with the smoothness, as well as automatically track the machine's start and stop events.

The Navigator’s GSI trace screen showing the simulated California profilograph graph.

• GSI (GOMACO Smoothness Indicator) utilizes compact and ruggedized CAN-based sonic sensors and a CAN-based digital slope sensor to read the smoothness profile anywhere on the slab’s surface.

• The GSI is mounted on lightweight aluminum to allow for easy handling and assembly with less maintenance.

• The lower profile mounting system allows the work bridge to be mounted directly above the GSI, if needed.

• A new mounting system places the GSI units evenly across the back of the paver for accurate measuring.

• Each GSI mount features a digital color LCD screen on each tracer bar providing digital diagnostics right at the sensor location.

• The optional Navigator's GSI screen provides a full diagnostics platform incorporating the GSI traces, bar insertion locations, transition adjusters, and G+ control in one location and on ground level.

An updated LCD display screen on each of the GSI tracer bars. The LCD screens provide digital diagnostics at the sensor location or can send readouts to the optional Navigator system attached on the side of the paver.

ENGINE

Consult for options available.

SERVICE CAPACITIES

Fuel reservoir: 160 gal. (606 L).

Oil reservoir: 230 gal. (871 L).

AUTOMATED CONTROL SYSTEM

Type: Electronic-over-hydraulic.

Controls: GOMACO’s exclusive G+® control system features self-diagnostics for grade and steering and smart steer controls for paving accuracy and ease in operation. It features multi-language, metric or imperial settings, and a 6.5 in. (165 mm) anti-glare display screen.

Control indicators: Color graphical performance indicators allow operator to monitor control signals for machine guidance on stringline or 3D.

WATER SYSTEM

High-pressure water system: Two 110 gal. (416.4 L) tanks.

High-pressure with trigger gun control and adjustable pressure unloader for up to 2000 psi.

Option: Two 150 gal. (567.8 L) tanks with hoses, nozzles, and 14.5 cfm (.41 cmm) air compressor for pressurized spray system.

SLIPFORM MOLD

One right-hand drive section, one left-hand drive section, and one center insert with power transition adjuster (PTA) section. Balance of inserts per customer specifications. Hydraulically pressure-compensated sideplates with variable depth adjustments.

International mold: One right-hand drive section, one left-hand drive section, and one power transition adjuster (PTA) section. Balance of metric inserts per customer specifications. Hydraulically pressure-compensated sideplates with variable depth adjustments.

VIBRATORS

Type: Hydraulic motor-in-head powering an eccentric weight.

Quantity: 16 vibrators and 30 vibrator circuits are standard.

AUGER SYSTEM

Type: Two strike-off auger circuits and two grout box auger circuits.

TAMPER SYSTEM

Type: Electronic-over-hydraulic circuitry. Hydraulically-powered split vertical tamping system.

Tamper speed: Adjustable up to 120 strokes per minute.

TWO-TRACK SYSTEM

Type: Two hydraulically powered, gear-driven crawler tracks.

Overall track length: Series 6 tracks, 12 ft. (3.66 m) includes track fender.

Track pad width: 15.75 in. (400 mm).

Track speed: Variable up to 28 fpm (8.53 mpm) paving, and auxiliary up to 85 fpm (25.91 mpm).

Ground pressure: 23 psi based on 80,100 lb. (36,333 kg) machine with mold and weight evenly distributed.

Leg height adjustment: 36 in. (914 mm) hydraulic adjustment and manual adjustment of 11.75 in. (298 mm) for a total height adjustment of 47.75 in. (1213 mm).

TELESCOPING FRAME

Telescoping: 20 in. (508 mm) deep modular roller frame telescopes up to 7 ft. (2.13 m) on both sides for a total of 14 ft. (4.27 m) of telescoping capability.

Paving widths: 40 ft. (12.19 m) maximum paving with frame inserts.

FOUR-TRACK SYSTEM

Type: Four hydraulically powered, gear-driven crawler tracks.

Overall track length: Series 6 tracks, 8.9 ft. (2.71 m) includes track fender.

Track pad width: 15.75 in. (400 mm).

Track speed: Variable up to 22 fpm (6.7 mpm) paving, and auxiliary up to 66 fpm (20 mpm).

Ground pressure: 21 psi based on 108,000 lb. (48,988 kg) machine with mold and weight evenly distributed.

Leg height adjustment: 36 in. (914 mm) hydraulic adjustment and manual adjustment up to 18 in. (457 mm) for a total height adjustment of 54 in. (1372 mm).

DIMENSIONS

Two-Track operational with 24 ft. (7.32 m) wide 5000 series open-front mold.

Operational length: 16.5 ft. (5.03 m) without the work bridge.

Operational width: 30 ft. (9.14 m).

Operational height: 11.9 ft. (3.63 m).

Two-Track transport without mold.

Minimum transport length: 20.1 ft. (6.13 m) or 18.6 ft. (5.67 m) with the ladders removed.

Minimum transport width: 12.1 ft. (3.69 m).

Minimum transport height: 10.6 ft. (3.23 m).

Minimum transport height with 24 ft. (7.32 m) 5000 Series mold: 10.9 ft. (3.32 m).

Four-Track operational with 24 ft. (7.32 m) 5000 series open-front mold.

Operational length: 27.4 ft. (8.35 m).

Operational width: 29.25 ft. (8.92 m).

Operational height: 12.1 ft. (3.69 m).

Four-Track transport without mold.

Minimum transport length: 36.3 ft. (11.06 m).

Minimum transport width: 9.5 ft. (2.9 m).

Minimum transport height: 10.6 ft. (3.23 m).

Minimum transport height with 24 ft. (7.32 m) 5000 Series mold: 10.9 ft. (3.32 m).

WEIGHTS (approximate)

Two-Track transport weight: 61,000 lbs. (27,669 kg) without mold.

Two-Track operational weight: 80,100 lbs. (36,333 kg) with a 24 ft. (7.32 m) wide 5000 series open-front mold.

Four-Track transport weight: 88,000 lbs. (39,916 kg) without mold.

Four-Track operational weight: 108,000 lbs. (48,988 kg) with 24 ft. (7.32 m) 5000 series open-front mold.

Note: Transport and operational weights and dimensions are variable, depending on the number of machine options.

ATTACHMENTS/OPTIONS

5000 series mold.

5400 series mold.

VHS, vertical hinged sideplates.

Auto-Float attachment.

Detachable telescoping auger/strike-off mold.

Computer-controlled power transition adjuster (PTA).

Ratchet-style edge slump.

Frame extensions.

GSI (GOMACO Smoothness Indicator).

Sideplate extensions for bar insertion.

Manual bar inserter.

Air-powered bar inserter.

Hydraulic bar inserter.

5400 series tie bar inserter.

Frame-mounted tie bar inserter.

Bolt-on keyway attachments.

Spreader plow.

GOMACO Remote Diagnostics (GRD).

On-board camera.

Navigator.

Other options are available to customize the machine to accommodate applications and customer needs.