GOMACO World Index --- GOMACO World 28.1 - May 2000

University Forum: To Knot Or Not

By Dennis Clausen, Director Of Training

Q. To knot or not to knot?

A.When setting stringline, it is recommended to use new stringline, or line that is in good to excellent condition. When using line that has been tied together several times, the knot becomes the weakest link. When attempting to pull the line to the proper tension, the place that it will break is usually in the knot. Proper line tension is attained when the line can be twisted by hand no more than 45 degrees. If the line can be twisted more than 45 degrees, the line is too loose. A loose line will cause gradual ups and downs (swales), as well as gradual ins and outs (alignment), in the finished product. Another problem caused by knots in the line is the long ends often left on the knot. When the grade sensor wand hits these long ends that are hanging down from the knot, it will cause the sensor wand to deflect. This will cause a bump in the finished product that the finishers will have to eliminate. If you must tie the line together (knot), make certain that the long ends are trimmed so they do not become entangled in the sensor wands.

Another stringline problem that may occur is when the end of the line holder rod has been bent open or closed. If the notch in the end of the rod has been bent open, the line can be lifted out of the holder by the sensor wand. If the end of the rod has been bent closed, the holder could damage the line when it is pushed into the notch, causing a weak spot in the line. If the end of the line holder is bent completely closed, do not simply place the line on top of the holder and tie it there (figure 1); replace the holder rod.

Proper set-up and maintenance of the stringline guide is important for the best possible results. Keep in mind that the machine follows the stringline and that any errors in line set-up will be reflected into the finished product. It is recommended that if the line is left up overnight that it be spot checked before resuming pouring operations. A quick way to check the line is to simply "eyeball" it (figure 2). That is to sight along the line and check for any noticeable irregularities. The line can also be spot checked off of the grade hubs (figure 3).

Q. The company I work for just purchased a new GP-2600 two-track. I will be in charge of the set up and operation of the machine. I was wondering if there was any advantage to using the walking stringline as opposed to a regular stringline. How would the ride compare?

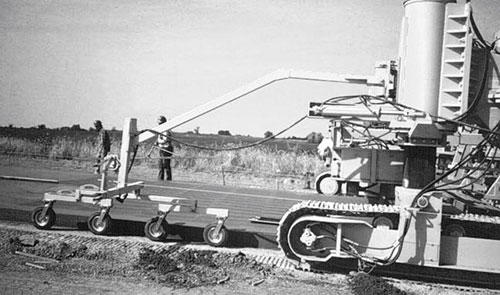

A. Use of the walking stringline (figure 4) is determined by the condition of the grade the assembly will be running on. If the grade is in good condition, then a walking stringline will give results that will be comparable with a regular stringline. However, if the grade the averaging wheels will be running on is uneven, then a regular stringline will give better results. Another thing to keep in mind when determining whether or not to use the walking stringline is the condition of the grade next to the averaging wheels. If haul trucks will be passing by next to the wheel track, they may "pump" the grade. This would cause an uneven grade for the wheels to run on. The advantage to using a walking stringline is that it is not necessary to set a line on one side of the paver. This is beneficial when using a placer/spreader in front of the paver, as the folding, or telescoping, belt would not become entangled in the stringline.

GOMACO University recently completed another successful season in Ida Grove, Iowa, with over 800 students attending the classes during the 15-week school season. Twenty-six different courses were taught covering operation, set-up, maintenance, trouble-shooting and other aspects of owning and operating various GOMACO equipment. The following pictures show highlights of the 2000 season. Thanks to everyone who attended GOMACO University this year. Good luck in the field!

Subscribe to Receive GOMACO World Magazine