GOMACO World Index --- GOMACO World 38.1 - July 2010

GOMACO Innovations and Introductions in 2010

• GOMACO GP-2400 Slipform Paver with Exclusive G+ Control System

• GOMACO Independent IDBI Attachment for Four-Track Slipform Pavers

• GOMACO 5400 Series Paving Mold

• GOMACO 5400 Series Bar Inserter

• Contractor Request Develops into a New Canopy for the Commander III

• 9500 Now Available with Optional Folding Rear Conveyor Belt

GOMACO GP-2400 Slipform Paver with Exclusive G+ Control System

Bituminex Paving Ltd. slipforms 16 feet (5 m) wide with their new GP-2400 paver on a parking lot project in Winnipeg, Manitoba, Canada.

A customer approached GOMACO recently with a very specific request for a new paver. They operate GOMACO HW-165 pavers and are either paving or transporting the machines every day during their short paving season in Canada. When they looked at the total amount of work they had on the books, they realized a new paver would be necessary for the 2010 season. Their wish list for the new paver included: half-width paving, tight-radius capable, user-friendly, maneuverable, easy to transport, and quick to set up. The result: the two-track GP-2400 slipform paver.

The first GP-2400 was equipped with eight foot (2.4 m), series two tracks, part of the customer request for a tight-radius capable machine. It features a telescoping frame with a 3100 series open-front mold that will slipform widths from 10 feet to 16.5 feet (3 to 5 m), without a frame insert. With a frame insert, it can pave widths up to 24 feet (7.3 m). Sixteen vibrator circuits are standard on the GP-2400.

It is powered by a 174.5 hp (129.5 kW) 6.6 Turbocharged Caterpillar® diesel engine. Two-speed track motors allow a fast 105 feet per minute (32 mpm) travel speed for quick maneuverability around the job site, while the low speed is variable up to 35 feet per minute (10.7 mpm).

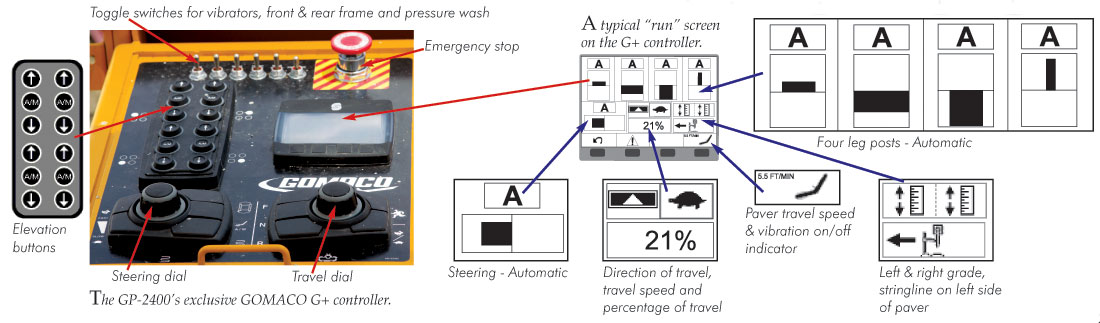

The GP-2400 features the exclusive GOMACO G+ control system with self-diagnostics for grade and steering. It is able to operate in several languages, by customer choice, and offers metric or imperial measurements. The G+ system has been designed all in-house by GOMACO's control experts. It features new and easy-to-operate hardware with steering and travel dials, while buttons are used to control steering and elevation. A screen on the control panel illustrates the various aspects of the paver.

GOMACO Independent IDBI Attachment for Four-Track Slipform Pavers

A four-track GHP-2800 slipforms 31 feet (9.4 m) wide with a new independent IDBI attachment on a project in Chicago, Illinois.

Almost three decades have passed since GOMACO Corporation revolutionized the concrete paving industry with the introduction of the GOMACO system for putting dowel bars into a concrete slab during the paving process. The GOMACO IDBI has been proven and accepted around the world for accuracy in bar placement location, productivity and meeting rideability specifications. GOMACO has once again created a revolution with the introduction of the independent IDBI attachment for all four-track GOMACO pavers.

The new IDBI attachment is an independent unit providing dowel bar insertion behind a paver to form the transverse joint. The IDBI attachment is a new generation bar insertion system. The attachment is powered by its own C4.4, Tier 3, diesel Caterpillar® engine with 91 hp (68 kW) @ 2300 rpm. No power or hydraulics is needed from the paver's engine. A CAN cable connects the IDBI's controls to the controller on the paver and allows the two systems to communicate. For example, when the GOMACO paver stops and starts, the tamper bar and screed on the IDBI turn on and off automatically in coordination with the paver. GOMACO engineers have designed a bar insertion concept and created an independent attachment that is self-contained and self-powered. The new design features a new IDBI tray that is stronger, more compact and makes width changes easier. New adjustable-height bar extractors allow contractors to quickly and easily change the setup for different bar sizes for insertion requirements.

The IDBI controls have all been designed in-house by GOMACO controls engineers. Its new GOMACO G+ control system features the same graphical display as the G22 controller, with easy to learn and easy to understand controls. The IDBI information is presented in full color, commands are presented in full text, and it is able to operate in several languages, by customer's choice. It offers the choice of metric or imperial measurements. The new IDBI control system also offers troubleshooting capabilities and other features that will make start up and general paving each day fast and easy.

The new independent IDBI attachment features it own outriggers to aid in attaching the unit to the paver and also for loading and unloading the unit for transporting. The outriggers can be hydraulically lowered and placed on the ground to support the full weight of the IDBI as it is attached to or detached from the paver. The outriggers on the attachment have 48 inches (1219 mm) of stroke and are also used to raise the unit so a trailer can be backed underneath for transport.

The IDBI attachment is available for all GOMACO four-track slipform pavers. Please visit, http://www. gomaco.com/Resources/idbi.html for more information.

GOMACO 5400 Series Paving Mold

GOMACO Corporation is proud to introduce the new 5400 series paving mold, designed with a structural integrity that is unmatched in the industry. The new series also includes a rear-loading, front-inserting 5400 series bar inserter, along with other bar placement attachments.

The mold, with a 54 inch (1372 mm) finishing length, has a new "box" design and durable 0.5 inch (13 mm) paving skin for structural integrity. It is available with a 20 inch (508 mm) auger or a spreader plow to move the material across the paving width. A newly designed strike-off is mounted to the paver's mainframe, independent of the mold. The strike-off has a modular design with a wedge-lock system for easy width changes. It has hydraulic crown adjustment with up to 10 inches (254 mm) of vertical hydraulic adjustment. The new mold also features hydraulic Vertical Hinged Sideplates (VHS), self-contained to the inside of the mold, allowing minimum track clearance.

The mold was built to be easy to assemble, with inserts that are bolted together with front and rear alignment pins. Vertically adjusting mounts on the mold allow precise leveling of the mold to the paver. A front and rear T-bar at the top of the mold adds structural integrity and is utilized for attaching paving accessories. A new vibrator mounting tube attaches to the T-bar on the mold and the vibrators can now be vertically raised or lowered to accommodate paving conditions or transporting needs.

The mold was also built to be versatile. The 5400 series mold will have optional telescoping end sections with 12 inches (305 mm) of width variation on each side. The transition adjustor is self-supported and driven with a 3.5 inch (89 mm) ACME screw for up to a six inch (152 mm) crown. Split, pressure-compensated sideplates allow a standard paving depth from zero to 24 inches (0 to 610 mm). The mold will also be available with edge slump, batter adjustment and optional tamper bar.

GOMACO 5400 Series Bar Inserter

The new 5400 series bar inserter offers ease of use with rear loading from the paver's work bridge, while the bar is inserted in front of the mold. It features a reliable and highly efficient bar loading chain system with bars traveling in a flat, straight path. The bar insertion process and timing is controlled by GOMACO's new G+ system. The new inserter mounts to the 5400 series mold's T-bar, where it can allow on-the-go crown changes while maintaining a constant bar depth. Individual depth guides on the right and left side of the bar inserter keep the bars parallel to the top of the slab during insertion. The system is able to accommodate #3 to #8 diameter bars between 20 to 40 inches (508 to 1016 mm) in length, and inserts the bars up to 7.5 inches (191 mm) deep into the concrete slab. The bar bundles are loaded into a bar box that is mounted to the paver's rear T-rail for easy access and loading of the bar magazine. The bar loading chain system and bar magazine are capable of holding up to 50 bars.

Please visit http://www.gomaco.com/Resources/5400seriesmold.html for more information about the 5400 series mold and bar inserter.

Contractor Request Develops into a New Canopy for the Commander III

Canadian contractor, Jean Le Clerc Excavation, approached GOMACO recently for a special request for their new Commander III... a canopy to help shield the operator from Canada's inclement weather. GOMACO engineers fulfilled the request with only a few, slight machine modifications. The operator's console was modified in order to house the necessary hydraulic and electrical components of the canopy. Support beams on either side of the console hydraulically raise or lower the support system for the canopy. The canopy itself swings manually into position over the operator's head. It has a plexiglass windshield that can be unpinned and lowered to shield the forward view of the operator.

9500 Now Available with Optional Folding Rear Conveyor Belt

The GOMACO 9500 trimmer or placer/spreader is now available with an optional rear folding conveyor. The new innovation is the direct result of a contractor request from APAC-Tennesee Inc. The option allows the conveyor to remain attached to the 9500 during shipping. The 9500's shipping length, with the new folding rear conveyor, is just 41.8 feet (12.7 m). Shipping height is 11.5 feet (3.5 m).

During the conveyor frame redesign process, engineers rebuilt the conveyor to be stronger and more rigid with a new, truss-style framework. The switch to control the hydraulic folding operation of the conveyor can be placed at different locations on the back of the machine, which allows ultimate operator visibility and safe operation.

The belt width is still 36 inches (914 mm) and the rear conveyor maintains its 160 degree swing with hydraulic height adjustment up to 12 feet (3.7 m). It has a 34.7 feet (10.6 m) long reach during machine operation, with a conveyor belt speed of 504 feet per minute (153.6 mpm) allowing fast placing of concrete or removal of trimmed material.

Subscribe to Receive GOMACO World Magazine