GOMACO World Index --- GOMACO World 41.1 - October 2013

New Batman Canal Irrigates Southeastern Turkey

One of the responsibilities of the Southeastern Anatolia Project (GAP) is the development of irrigation systems in southeastern Turkey. GAP oversees nine provinces and approximately 10 percent of Turkey’s total population, covering a surface area of 75,000 square kilometers (28,960 mi2). One of the GAP projects is a new concrete canal stretching approximately 140 kilometers (87 mi) between the cities of Batman and Diyarbakır in southeastern Turkey. The formal name of the project is the Batman Irrigation Canal.

Fernas Construction and Trade Corp., based out of Ankara, Turkey, specializes in hydroelectric power plants and irrigation projects. The company is responsible for building this new canal and lining it with a 100 millimeter (4 in) thick layer of concrete. They chose the GOMACO four-track GP-2600 to slipform all of the canal on the project. It would be the company’s first slipforming project.

Many hours of planning and engineering had to be accomplished before the first concrete could be placed. The scope of the project included two phases, the Batman Irrigation Left Coast and Right Coast Canals. Between the two, there were 47 different canal sections with varying canal dimensions and slopes. The overall width of the canals varied from 13.2 meters (43.3 ft) to 2.35 meters (7.7 ft). Slope lengths varied from 5.23 meters (17.2 ft) to as short as 0.81 meter (2.7 ft). The biggest challenge for the project would be developing one machine and as few molds as possible for the different profiles.

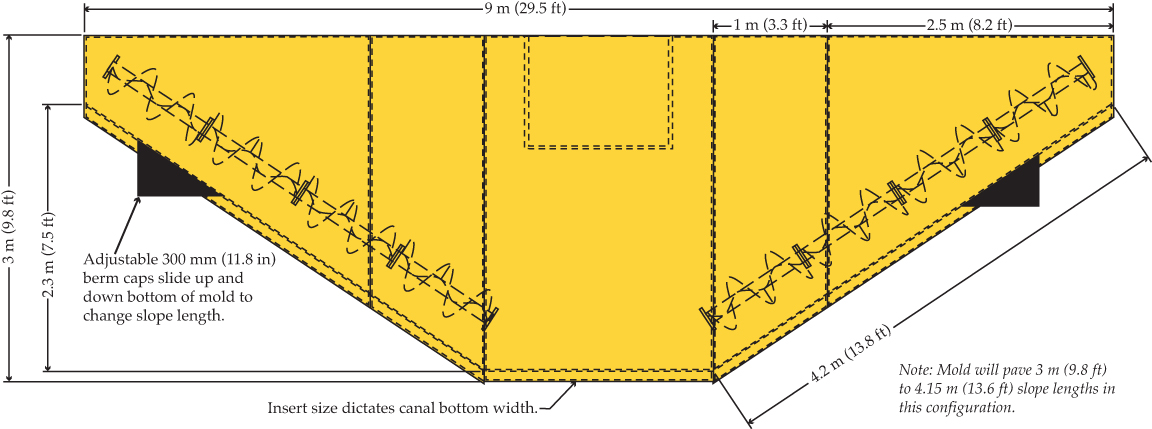

Engineers from Fernas Construction worked closely with GOMACO engineers to create a solution. The four-track GP-2600 would be equipped with only two molds. A single slope canal mold would be used for canal widths over nine meters (29.5 ft).

Canal widths nine meters (29.5 ft) and less would be slipformed in one paving pass using a sectional trapezoidal mold that could be adjusted for slope and depth. The sectional mold and front hopper feature different inserts to change the slope and the depth. A sliding adjustable berm cap on either side of the mold allows an extra 300 millimeters (11.8 in) of slope length adjustment. To coordinate all of these transitions while working on site, GOMACO engineers provided a set of charts for canal widths and depths with instructions for the paver’s framework, mold, and trimmer conversions.

With the paver plan in place, slipforming on the Batman Canal could begin. The profile of the canal was dug with excavators. A chain trimmer on the front of the GP-2600 is used to trim down the high spots in the grade.

Four mobile batch plants are on site, each with the ability to produce 60 cubic meters (78.5 yd3) of concrete per hour. The concrete is a Class C16/20 mix, 24.3 MPa (3000 psi), with a 2.3 percent air entrainment. Slump averages 60 millimeters (2.4 in).

Concrete is transported in ready-mix trucks to the paving site. The trucks discharge onto a conveyor which dumps into and fills the hopper of the canal mold.

Behind the paver, finishers stand on a work bridge and apply a trowel finish to the surface of the canal. Transverse and longitudinal joints are cut into the new concrete every three meters (9.8 ft). Paving production for the wider width profiles averages approximately 600 meters (1969 ft) per day.

Service personnel from both GOMACO International Ltd. in England and GOMACO’s distributor in Turkey, Göker, were on site at various times during the canal paving. The service personnel were available to aid in machine start-up, training, technical and application support during paving.

“When we were looking to buy a machine, we were looking for a quality machine with a quality dealer for after sale and brand,” Kadir Özkan, Project Manager for Fernas Construction, said. “The GP-2600 has easily handled all the dimensions in the project with its half-width and full width molds.”

Once the Batman Canal is complete, it will provide irrigation for an 18,593 hectare (45,944 acre) area stretching from the dam and hydroelectric power plant on the Batman River into the city of Diyarbakır.

Subscribe to Receive GOMACO World Magazine