GOMACO World Index --- GOMACO World 36.2 - July 2008

The All-American Canal: Slipforming 72 Feet (21.9 m) Wide...

Coffman Specialties has always wanted to do canal work. It’s been a goal for the company, a project they have been anticipating for several years and one challenge they had yet to accomplish. Through the years, they have talked with various canal paving experts, researched equipment, and discussed the various aspects of canal paving.

The company is not afraid of taking on the larger, more difficult slipforming projects near their company headquarters in San Diego, California. They’ve taken on challenging projects on airports, air bases, and highways, including Sky Harbor Airport in Phoenix, Arizona, Moffett Naval Air Station in San Jose, California, McClellan Air Force Base in Sacramento, California, and a large paving project in the Philippines. All the while Coffman Specialties had perfected their craft as slipform pavers. They were ready for another challenge.

A Canal in Southern California –

When the decision came down that a portion of the All-American Canal through the Imperial Valley in California would be lined with concrete, the company saw their chance to once again realize their canal paving goal. Jim Coffman, project coordinator and operation’s manager for Coffman Specialities, and his son Kevin, vice president, started to assemble their team of canal experts. The All-American was the canal challenge they wanted, the one they had been waiting for all these years.

They knew for certain they wanted a machine that would incorporate the latest technology available in the marketplace today. They wanted a machine that could slipform the new canal in just two paving passes. And they knew the machine would have to be large enough to accommodate the size and the scope of the All-American Canal.

“We’ve done our research and watched other canal paving operations in the past,” Jim Coffman explained. “We’ve seen the size of their equipment. We also noticed that most of the canals of the slipform type, both the trimmer or the paver, is of a 1960s or 1970s vintage, and the technology being utilized is old technology.”

Coffmans were determined that when they won the bid, they would give the canal’s owner, the Imperial Irrigation District (IID), the best product possible. Building on a 30-year relationship, they brought the project specifications, their ideas and opinions to GOMACO to develop the equipment for this massive project.

“We chose GOMACO because we have a long-standing relationship with the company,” Jim Coffman said. “We looked at other manufacturers, but GOMACO, in our view, has the best R&D department. One of the things that drew us to this project, was to use current technology and apply it to the actual paving of the canal prism.

“GOMACO has a commitment to excellence and they also have a commitment to customer satisfaction. We felt we could work with them, relative to the design and the construction of the canal paver, so we would be satisfied with the end product.”

Coffman Specialties won the bid to pave Reaches Two and Three of the All-American Canal project. In May 2006, they contracted with GOMACO to build three pieces of canal equipment with delivery required by the end of the year. GOMACO was about to begin their own design/build project to get Coffman the specialized equipment they needed in time to begin their project.

Coffman Specialties slipformed portions of the All-American Canal 72 feet (21.9 m) wide in a single pass with their new GOMACO equipment.

The original All-American Canal was unlined and substantial amounts of water was lost due to seepage. A new concrete-lined canal will help minimize water lost.

GOMACO Takes On the Challenge –

“It was a massive task to undertake and required a huge amount of coordination, cooperation and effort from R&D, engineering, purchasing and all of manufacturing,” Kevin Klein, vice president of R&D, said. “I think we were ready to take on a challenge of this size.”

The deadline for the equipment also created a challenge. GOMACO had to implement some new techniques to the manufacturing process.

“Drawings were being released to the floor as soon as they became available,” Jim Homan, GOMACO’s assistant manager of R&D and the All-American Canal project manager, said. “With such a tight deadline on the project, we couldn’t afford to wait until everything was designed and drawn. Instead, we built the machines in pieces and final assembled later. It was a new way of thinking and handling things in the building process.”

Several hours were spent in meetings between GOMACO and Coffman Specialties personnel during the design phases of the equipment.

Other aspects of the project included quality and tolerance checks of materials from the very beginning. Each part or product was inspected when it arrived at GOMACO to ensure that everything was built to specifications. Every piece of the equipment was accompanied with a green job sheet. The color instantly identified it as a piece of the All-American Canal equipment as it worked its way through the plant. A special staging area, large enough to accommodate the large scope of the equipment, was also created for the finished pieces.

“Communication was the key to our success, through all departments and areas of construction,” Homan said. “Meetings were held at the very beginning of the project with production supervisors and other key personnel in both of our manufacturing facilities to make sure they were aware of the scope of the project and the additional demands on their departments. Meetings continued to be held on a daily basis to keep the project on track and to potentially defuse any problem areas.”

Meetings were also held with Coffman Specialties and their team of canal experts, both in Ida Grove and in California.

“Those meetings were imperative,” Jim Coffman said. “It allowed us to interact and communicate, and ultimately build something that worked very well.”

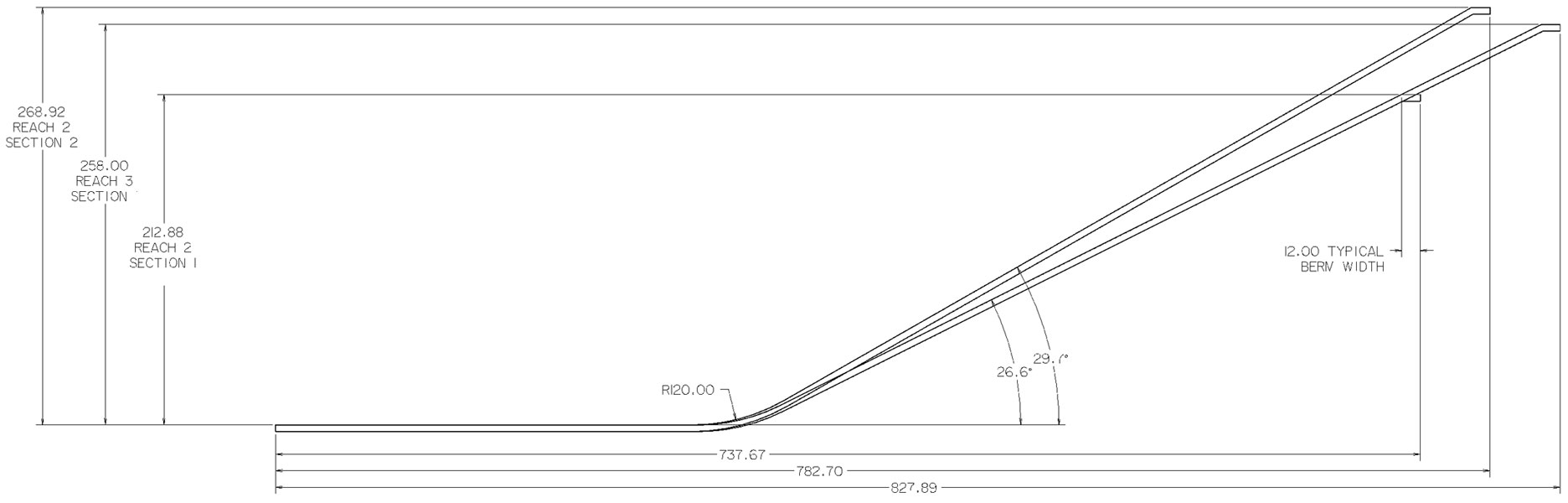

The scope of the canal... It is 50 feet (15.2 m) wide across the bottom, wide enough for four lanes of traffic, and approximately 150 feet (45.7 m) wide across the top. Coffman Specialties paved the new canal in two passes.

The All-American Canal Reaches Two and Three –

The entire All-American Canal lining project called for a new 23 mile (37 km) long concrete-lined canal to be built parallel to the existing unlined canal.

Coffman Specialties would pave the six mile (9.7 km) long Reach Two and four mile (6.4 km) long Reach Three of the project. The proposed lined sections would have slopes of 1.75:1 and 2:1, a bottom width of 50 feet (15.2 m) and a top width spanning 150 feet (45.7 m).

Slope widths would be variable, between 37.3 feet (11.4 m) and 45.7 feet (14 m). The concrete lining itself would be four inches (102 mm) thick.

The All-American Canal In GOMACO World Vol. 36, No. 2

Page 1 - Page 2 - Page 3 - Page 4 - Page 5 - Page 6 - Page 7 - Page 8 - Page 9 - Page 10