GOMACO World Index --- GOMACO World 40.2 - October 2012

THIS is a Paving Project– The I-15 CORE - Page 5

The GP-4000 with IDBI Attachment

The GOMACO four-track GP-4000 with IDBI attachment and its crew have been responsible for slipforming the project’s long mainline runs. It has been utilized at various paving widths along the project, 36 and 39 feet (11 and 11.9 m) on the southern portion of the project, and 24 and 26 feet (7.3 and 7.9 m) wide on the northern portion.

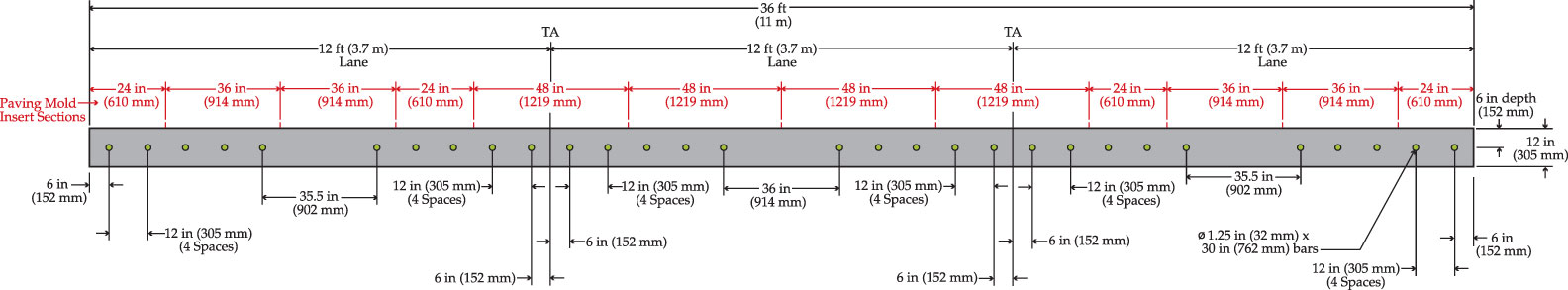

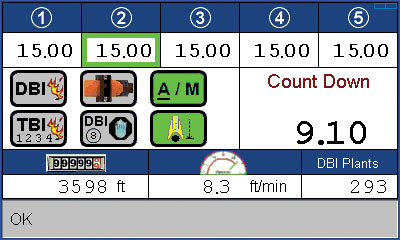

UDOT specifications require a transverse joint every 15 feet (4.6 m). The IDBI attachment inserts ten dowel bars, 1.5 inches (38 mm) in diameter and 18 inches (457 mm) long, in each lane of travel. The IDBI’s G+TM, GOMACO’s proprietary control system, manages the insertion process. The IDBI information is presented in full color and commands are presented in full text for an easy-to-operate system.

“It makes the IDBI really user-friendly,” Sink said. “And troubleshooting is so much easier with the G+. It makes it easy to find something that is potentially wrong with either the feedbacks or sensors.”

“The G+ is very simple,” Steeves added. “You have to understand the concept of what the IDBI does and then it’s a matter of going through the G+ controller, and it tells you exactly what it’s going to do. It makes the process very simple.”

One or two front-mounted tiebar inserters, depending on the paving width, insert epoxy-coated bars 0.625 inches (16 mm) in diameter and 30 inches (762 mm) long. The bars are placed at 30 inch (762 mm) intervals.

Paving production for the GP-4000 with IDBI attachment averages 3500 cubic yards (2676 m3) in a 14-hour paving day. The PI has averaged around two inches (51 mm) on the project for the GP-4000 with IDBI.

“Our best production day with the paver, and the record for the project, was 6450 cubic yards (4931 m3) in a 14-hour period,” Sink said. “We had 36 trucks feeding us out of two of the batch plants. It was an impressive day.

“I started on this project in September 2010 and helped assemble the GP-4000. We’ve been together ever since and I wouldn’t trade it for any other paver on the project. It’s a good machine and the IDBI makes it a really fast machine, makes it a producing machine, and I enjoy working with it.”

An engineers’ drawing illustrates the IDBI attachment’s bar placement, as specified by Utah Department of Transportation, when the GP-4000 is paving 36 feet (11 m) wide.

The IDBI inserts bars every 15 feet (4.6 m) as shown on the G+ control screen.

Utah County I-15 Corridor Expansion - GOMACO World Vol. 40, No. 2

Page 1 - Page 2 - Page 3 - Page 4 - Page 5 - Page 6 - Page 7 - Page 8 - Page 9 - Page 10 - Page 11 - Page 12 - Page 13